PDF list

- Garantiebestimmungen: click there to view details.

- VectorDigital product catalogue: click there to view details.

- Data sheet: click there to view details.

- Bedienungsanleitung: click there to view details.

- Technical Details: click there to view details.

- Warranty conditions: click there to view details.

Descript of Plasmaschneider CUT 70 S

Steel Mill - Just incredibly strong!

You are looking for quality , look for service, you are looking for good prices , look reliability !

What you should therefore take as a customer? - Confidence!

Our key terms for trust are :

Purchase at a retailer or directly from the manufacturer - the steel plant.

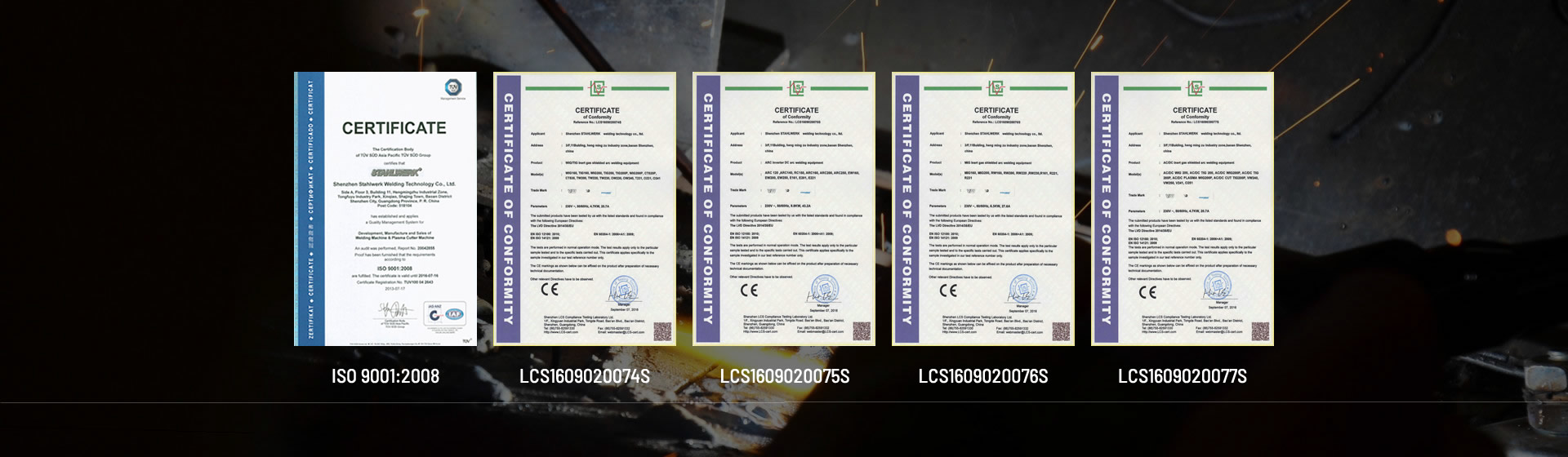

Markings and warranty information.

Long-term supply of spare parts .

Repair service in-house.

Invoice including VAT.

Steel Mill - Everything from one source!

We are not saying that you need to buy from us! But if they do - you will benefit from the most advanced solutions , the efficiency and the ongoing support we guarantee you a manufacturer.

We grow with the demands of our customers and we also offer:

5 years GUARANTEED satisfaction = 2 J. tot. Warranty + 3 year extended warranty !

Welding test .

Friendly and fast service.

Competent advice .

Flexibility.

Always an open ear for your wishes .

Best quality at fair prices.

Our - corresponding also the highest quality standards - equipment will be presented at all renowned welding and cutting shows.

Important functions & device information at a glance

ALL IMPORTANT PARAMETERS IN DIRECT ACCESS

ALL IMPORTANT PARAMETERS IN DIRECT ACCESS

Switch in the handle integrated ( comparable models work with cable ties) .

Digital display.

Cutting capacity up to 25 mm, depending on material .

The device uses a high- frequency ignition , without contact with the workpiece . (Advantage: more precise and faster cutting ) .

Small cutting width.

High cutting speed.

Good cutting quality.

High-quality nozzles and electrodes.

Duty cycle 60 % at 70 A.

Duty cycle 100 % at 50 A.

The cutting current is continuously adjustable between 10 and 70A .

Due to the small deformation thin plates can be welded together again immediately .

Accurate and very stable arc . Perfect for cutting of oil tanks , tubs, or similar body .

The device is immediately ready for use upon delivery.

The inverter technology also enables a huge reduction in both weight and volume of the transformer , and of the compensating resistance. Thus, it is possible to develop a device that weighs only 15 kg with a professional performance.

Use the CUT 70 accepts all conductive metals such as Standard steel, copper, stainless steel, brass , aluminum, titanium cutting , etc. . The cutting current is 10-70 amps continuously variable. Cutting an air compressor with at least 6.5 bar , and requires 140 liters per minute. ( No more expensive gas ) A commercial building market compressor is also sufficient . Please pay attention to the performance.

In order to work with this device, you only need :

1 The plasma cutter itself, as well

2 Air compressor.

3 Automatic Helm / privacy .

4 Welding gloves.

| Anzeige des Ausgangsstroms | 10 - 70 A |

| Luftströmung | mind. 140 L/Min |

| Schutzart | IP 21 |

| Isolationsklasse | F |

| Netzspannung | 400 V AC |

| Netzfrequenz | 50/60 Hz |

| Netzsicherung (Träge) | 1 x 16 A |

| Einschaltdauer bei 60 A | 60% (30-35 Min.) |

| Einschaltdauer bei 40 A | 100% (1 Std.) |

| Luftdruck | 6,5 Bar |

| Gewicht | 18,5 Kg |

| Maße LBH (mm) | 560 × 220 × 430 |

| Normen | IEC 60 974-1; CE |

| Schneidstärke (Materialabhängig) | 25 mm |

| Schnittbreite | 1,2 mm |

| Lichtbogenführung | HF-Hochfrequenz |

English

English 简体中文

简体中文