PDF list

- Garantiebestimmungen: click there to view details.

- VectorDigital product catalogue: click there to view details.

- Data sheet: click there to view details.

- Bedienungsanleitung: click there to view details.

- Technical Details: click there to view details.

- Warranty conditions: click there to view details.

Descript of Milano 2300 Kombi Schweißgerät DC MIG MAG 200A WIG MMA FCAW E-Hand Inverter Schutzgas + Handschuhe

Important functions & device information at a glance

| Milan 2300 |  | ||

Quick | Light industrial Application: Thin sheet metal fabrication workshops Agriculture Car repair Shipyards and offshore industry | Process: MAG (GMAW) MIG (GMAW) Stick (SMAW) WIG (GTAW) | Input Power: 230V, 1-Phase Amperage Range: 5-200A Rated Output at 40 C (104 F): MIG: 200A at 18V @ 40% Duty Cycle MMA: 170A at 26.8V @ 30% Duty Cycle WIG: 200A at 18V @ 40% Duty Cycle Weight: 14 KG |

For TIG and Stick Welding

| Easier welding and economical choice. |

| Milan2300 is a very simple MIG/MAG welding machine, very easy to use

even if without any experience, Super mobility of weight 14kg can let

you do welding everywhere. Get in an economical cost it can also bring

you MMA process so it could be also used for electrodes. Based on

inverter system, Milan2300 offering fast arc response and precise arc

ignition, also saves up to 50% on input power and increases tack and

welding speed to twice that of traditional welding rectifiers. Easy operation and full functions: From the control panel allowing fast adjustment of all necessary controls for DC TIG welding with HF ignition. It?s also very convenient to store or take out the welding parameters from the memory. |

| Specialist Features: | |

| ♦ Full digitized control system, new energy efficient IGBT inverter power source, very simple and friendly operations. |  |

| ♦ Very clear wire melting drop transfer, very few spatters | |

| ♦ Powerful peak current confirms deep penetration and wide welding capacity. | |

| ♦ Dynamic control with a push of a button. | |

| ♦ Fast, precise, clean arc ignition to ensure the sccess ratio and arc ending. | |

| ♦ Weights at a mere 14 kg making it easy to carry around the shop or job site. | |

| Outstanding Quality: |

| ♦ Newly designed using the latest power electronic technology for improved reliability. |

| ♦ CE Certified. |

| ♦ 2 Years Warranty on parts , 5 Years Warranty on Transformer |

Technical specifications

| Description | SWIM DIGITAL Milan2300 |

| Weight | 14 kg |

| Power Source Dimensions | H490mmxW225mmxD380mm |

| Cooling | Fan Cooled |

| Welder Type | Multi Process Inverter Power Source |

| European Standards | EN 60974-1 / IEC 60974-1 |

| Number of Phases | 1 |

| Nominal Supply Voltage | 230V +/- 15% |

| Nominal Supply Frequency | 50/60Hz |

| Welding Current Range (DC STICK Mode) | 10-170A |

| Welding Current Range (DC TIG Mode) | 10-200A |

| Effective Input Current /STICK /TIG | 16.8A |

| Maximum Input Current/STICK/ TIG | 30.9A |

| Single Phase Generator Requirement | 15KVA |

| STICK (MMA) Welding Output, 40℃, 10 min. | 170A @ 30%, 26.8V 93A @ 100%, 23.7V |

| TIG (GTAW) Welding Output, 40℃, 10 min. | 200A @ 40%, 18V 126A @ 100%, 15V |

| Open circuit voltage | 60V DC |

| Protection Class | IP23 |

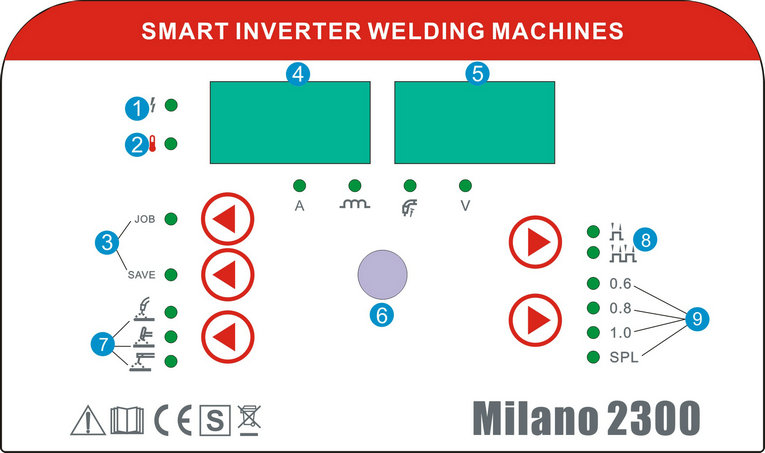

| General View of Control Panel |

| Control Panel Parameter Values | ||

1. Power Indicator 2. Fault Indicator 3. JOB and SAVE 4. Digital Anmeter | 5. Digital Voltmeter 6. Selecting function Button /Positive Control / Negative Control | 7. Weld Process Selection Button 8. 2T - 4T Trigger Latch Button 9. 0.6/0.8/1.0/SPL |

| The short-circuiting metal transfer mode | |

| The short-circuiting metal transfer mode is the low heat input mode of metal transfer for GMAW and has higher electrode efficiencies, 93% or more. The low heat input reduces weldment distortion and makes it ideal for sheet metal thickness materials. |

|

| Dynamic Control | ||

| Arc setting:soft | Arc setting:medium | Arc setting:hard |

|

|

|

| 1~4 Arc Crater Current | 5 Arc Crater Voltage | 6~10 Arc Dynamics |

| Dynamic control with a push of a button You know how it is from experience. Every transformer system has its own unique characteristics.One system produces a slightly softer arc,while the next generates a slightly harder arc.More important,every welder has his own preference in terms of what he considers to be the perfect arc: softer and longer,shorter and harder or somewhere in between.This calls for a level of distinction that transformer systems simply cannot realise.Our system allows you to individually adjust the dynamics of the arc to adopt the work and welding position at hand and will find the simplest and fastest arc setting that is most suitable in each case.The rest of the job is carried out by the intelligent arc control technology incorporated into the background to achieve a perfect weld seam every time. | ||

| 2-Rolls Drive System | |

| 2-Rolls wire-feeder with strong feeding motor. 2-rolls drive system delivers the electrode to the welding torch. It provides a stable wire speed and is popular for industrial applications. |

Accessories

| For Standard accessories | ||

|

|

|

| MIG torch: MB15AK Euro Connector Cable length 3M | Electrode holder with cable 2.5M200A | Earth clamp with cable 2.5M200A |

| For Standard accessories | ||

|

|

|

| Argon gas regular | Trolley: | MIG torch: DGB 240W Cooling Method: Water-Cooled Rating: CO2 300A Rating: Mixed Gas 270A Duty Cycle: 100% Wire Size: 0.8-1.2 Minimum Water Flow: 1.2 l/min Minimum Water Inlet Pressure: 2.0Bar Minimum Cooling Requirements: 900W Maximum Water Inlet Pressure: 5.0Bar Maximum Water Inlet Temperature: 50? |

| Shipping weight: | 15,20 Kg |

| Product weight: | 14,20 Kg |

| Dimensions( length × width × height): | 38,00 × 22,50 × 49,00 cm |

English

English 简体中文

简体中文